台积电一口气发三个新技术,又打了英特尔的脸?

台积电推出新的芯片技术,再一次巩固了晶圆制造龙头的地位。

面对三星和英特尔的强力追赶,台积电的龙头地位正受到空前挑战。英特尔更是喊出了 “重新夺回世界芯片制造桂冠” 的口号。究竟是会被超越,还是将继续稳坐宝座?

近日,台积电在北美技术论坛发布了一系列新型芯片技术,又一次遥遥领先。新型技术的发布,是台积电对三星和英特尔挑战的有力回应。会后,许多分析师认为,英特尔重新夺回芯片制造桂冠的说法过于乐观。

1、推出 3D 光学引擎,布局下一代通信技术

台积电准备用造芯片的方式造光模块,省功耗、省空间。

当前通信网络采用的光模块技术,主要是把各个组件组装在一起(见下图)。

这种集成方式随着传输速率的提升,会产生高功耗的问题。

为了解决这一问题,台积电推出了一种新的光模块产品。简单来讲,就是把制作芯片的那套技术,用在了光模块的制作上。这种方法,使得光模块体积大幅减小,材料成本、芯片成本、封装成本也进一步得到优化。

这是一种新型光模块技术,也是业内公认的下一代通信技术。

(台积电 1.6T 光引擎产品图)

然而,台积电并不是硅光领域的唯一布局者,Global Foundries、IMEC、PowerJazz 等厂商也早早做了布局。由于硅光芯片不是先进制程,通常在 45nm~130nm 之间,国内硅光设计公司基本都是找 Global Foundries,IMEC,PowerJazz 这些厂商做代工。

与同行相比,台积电进入硅光市场的时间相对较晚,但仍然领先于英特尔和三星。此外,这次大会上,台积电披露了雄心勃勃的光引擎战略,一年一迭代:25 年推出 1.6T 可插拔光学引擎,26 年推出 6.4T 光引擎。

考虑到台积电在芯片制造领域的绝对地位,以及公司制定的雄心勃勃的产品战略,未来在硅光市场,台积电会是一股不可忽视的力量,也许会抢占本身就在这一领域发展的公司的市场份额。

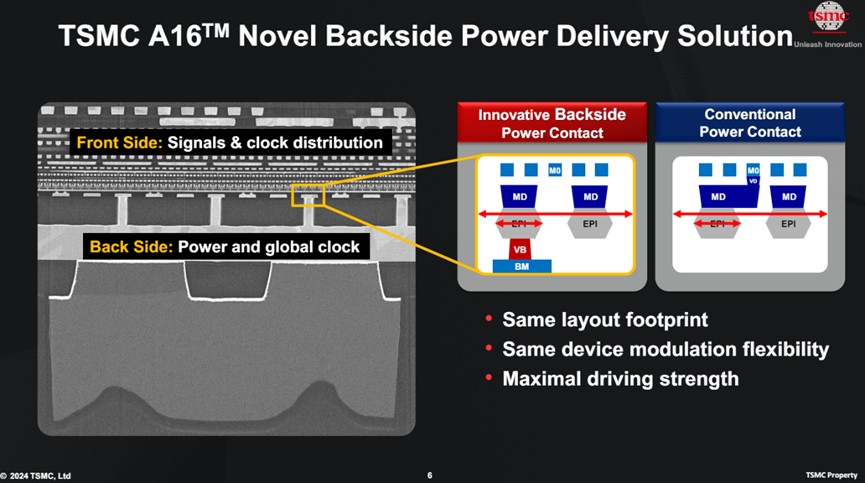

2、背面供电,助力高性能芯片需求

用全新供电方式,提升芯片的空间利用率。

关于芯片的供电方式,目前市场的主流做法是把电源部署在芯片的正面,这会导致电源挤占芯片空间。

台积电此次推出的背面供电技术,解决了这一问题。

除了台积电,IMEC 和英特尔也积极研发背面供电技术。三者相比,IMEC 的技术成本最低,但性能逊于台积电;台积电的技术成本最高,但性能最好。总的来看,台积电在背面供电技术上更胜一筹。

总体而言,台积电的新型背底供电解决方案是一项创新技术,可以提高芯片的性能、功耗效率和面积利用率。有望在未来的移动设备和数据中心芯片中得到广泛应用。

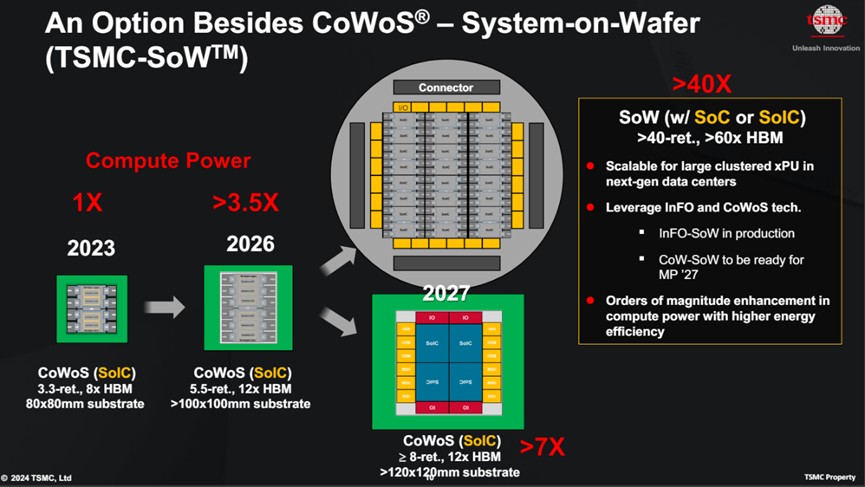

3、3D 封装之外,一种新的选择 —— “晶圆级系统”

通过在晶圆上互连芯片,让不受空间限制的数据中心,获得更快的互连速度。

随着芯片上晶体管的增多,市场对芯片集成度的要求也越来越高。特别是手机/电脑等终端,芯片无法做的很大,必须小巧,因此主要采用 3D 封装来集成芯片(垂直堆叠芯片)。

但面对数据中心这样,对芯片面积要求不是很高的场景。台积电推出了一种新的芯片集成方案 —— “晶圆级系统”。

该技术将多个芯片直接在晶圆上互连,更多的是在横向去扩展芯片系统(见下图),预计未来封装后尺寸将达到 12x12cm。

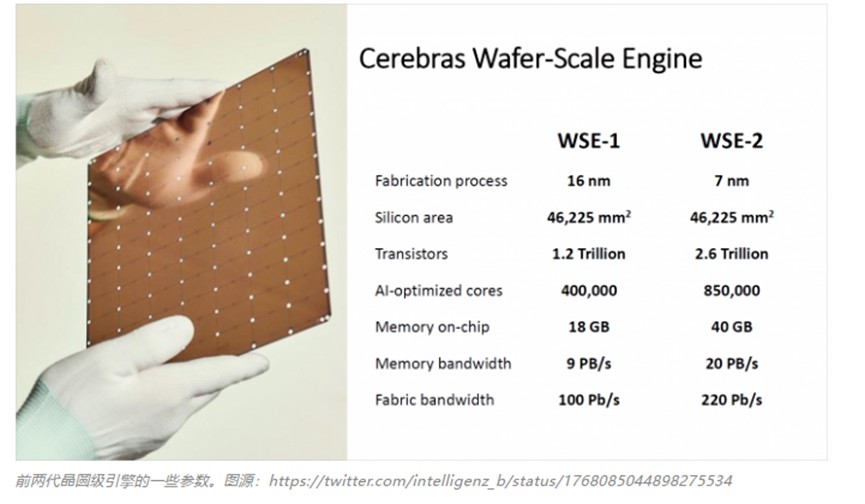

台积电使用该技术已经陆续推出了不少产品。例如,英伟达今年推出的 B100 GPU,由两个 Blackwell 小芯片组成一个 B100 芯片;Cerebras 的 “大芯片”,同一片晶圆上连接了 90 万个核心。

在晶圆级互连上,台积电也远远领先于英特尔和三星这两大对手。

总的来看,台积电的龙头地位虽然受到挑战,但仍然是晶圆领域的霸主。而英特尔夸下的海口,还没那么容易实现。